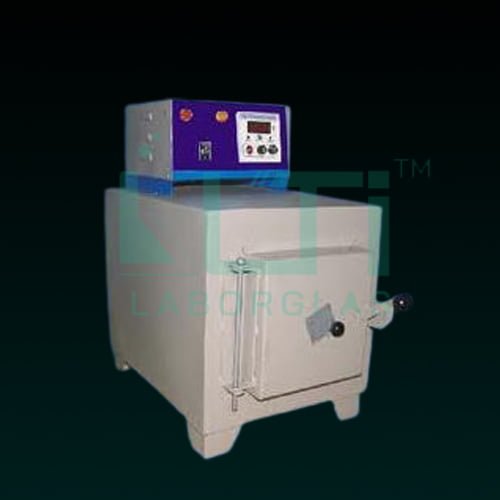

Features:

- Newly designed muffle furnace now has rapid heating and light weight construction

- Most useful for ashing, igniting and heat treading of small parts in chemical and industrial field, college and schools

- Special ceramic insulation makes furnace light weight

- Exterior of heavy gauge M.S/G.I duly finished in epoxy powder coated shade in regular Model

- Exterior S.S matt finish in GMP Model

- Solid state electronic temp.controller with digital indicator an CR/AL sensor

- Uniform heat distribution through all 4 sides kanthal A-I elements

- A special solid state fuse for protection to elements in case of over heating

- Maximum temperature: 1000c working temperature: 960 c

- Operates on 230 volts A.C.

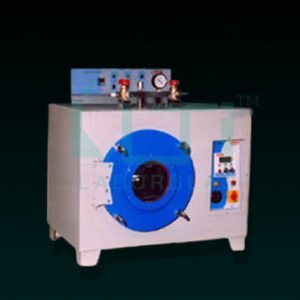

A Muffle Furnace in a laboratory is commonly used for:

- High-Temperature Heat Treatment: Conducting controlled heat treatment processes.

- Ashing: Burning off organic materials to leave behind ash for analysis.

- Sintering: Bonding particles in ceramics through controlled heating.

- Material Testing: Studying the behavior of materials under extreme heat conditions.

- Laboratory Experiments: Utilized in scientific research for controlled high-temperature studies.

- Quality Control: Ensuring consistent conditions for testing and analysis.

- Metallurgical Processes: Applied in metallurgy for various heat treatment applications.

- Industrial Manufacturing: Employed in industries for specific high-temperature processes.

- Annealing: Controlling the cooling of materials after heating.

- Ceramic and Glass Processing: Firing and shaping ceramic and glass materials at high temperatures.