Features:

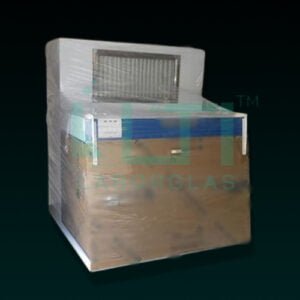

- Forced Air Hy Dry oven Usable in chemical pharmaceutical dye buff colors food products textile printing electrical and many other industries

- Engineered for complete reliability and excellent performance

- Constructed from M.S angle frame covered with heavy gauge G.I sheet duly finished in epoxy powder coated shade and inner S.S in regular Model

- High grade glass wool insulation between the wall minimize the heat loss

- Specially designed GMP Model having inner 316L and exterior 304 S.S Matt finish

- Evenly distributed elements ensure optimum heat transfer and uniform heating

- Forced air circulation for internal circulation re- circulation discharge of vapor vent and fresh air in take

- Digital read out continuously display process temperature and time control panel includes main digital controller with digital timer indicator lamp, main switch booster switches volts meter amp meter etc

A Forced Air Hy Dry Oven is specialized equipment designed for drying applications with forced air circulation. Here’s a brief overview of its uses:

- Uniform Drying: Utilized for achieving uniform and rapid drying of materials through forced air circulation.

- Moisture Removal: Applied for efficient removal of moisture from various substances or products.

- Laboratory Experiments: Found in laboratories for experiments requiring controlled and consistent drying conditions.

- Industrial Drying: Used in industrial settings for drying components, parts, or products on a larger scale.

- Quality Control: Employed for quality control processes to ensure specific moisture content in materials.

- Precision Temperature Control: Equipped with precise temperature controls for accurate and reproducible drying conditions.

- Research and Development: Widely used in R&D activities for testing and developing drying processes.

- Materials Processing: Integral in processes where controlled moisture removal is critical for the final product.