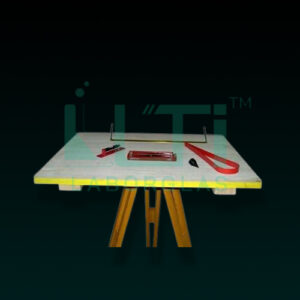

- SIEVE SHAKER (GYRATORY TYPE) driven by a 0.25 H.P. motor, 220 volt A.C. through a reduction gear and is suitable to carry upto 7 sieves of 12” or 8″ dia.

- When clamped the sieve table does not rotate but is inclined from the vertical axis and the direction of inclination changes progressively in the clockwise direction.

- In addition to the gyratory motion of the shaker there is an upward and downward movement at a frequency of 270 r.p.m.

- The whole mechanism runs in oil bath and the table can be unclamped to give an additional rotary motion.

- Analog Timer 0-60mins is inbuilt in the shaker.

A sieve shaker with gyratory motion serves various purposes in short form:

- Particle Size Analysis:

- Determine the particle size distribution of granular materials for quality control and research.

- Quality Assurance in Construction:

- Ensure the uniformity of construction materials like aggregates through particle size testing.

- Soil Analysis:

- Analyze soil samples to understand their composition and classify them based on particle size.

- Pharmaceutical Granule Sizing:

- Assess the particle size of pharmaceutical granules for quality control in drug manufacturing.

- Food Industry Quality Control:

- Monitor and maintain the consistency of particle size in food processing for quality assurance.

- Chemical Processing:

- Optimize chemical processes by analyzing and controlling the particle size of powders and granules.

- Mining and Minerals:

- Evaluate the particle size distribution of minerals and ores for efficient processing.

- Environmental Testing:

- Determine the particle size distribution in environmental samples to study sedimentation patterns.

- Research and Development:

- Aid in various research applications where particle size analysis is crucial for experimentation.

- Powder Characterization:

- Characterize powders used in industries like cosmetics, ceramics, and powder metallurgy.

- Pharmaceutical Formulation:

- Support pharmaceutical formulation by ensuring the appropriate particle size of active ingredients.

- Cement Industry:

- Monitor and control the particle size of cement materials for quality in the construction industry.