Features:

- Especially suited for application requiring radial and linear temperature uniformity

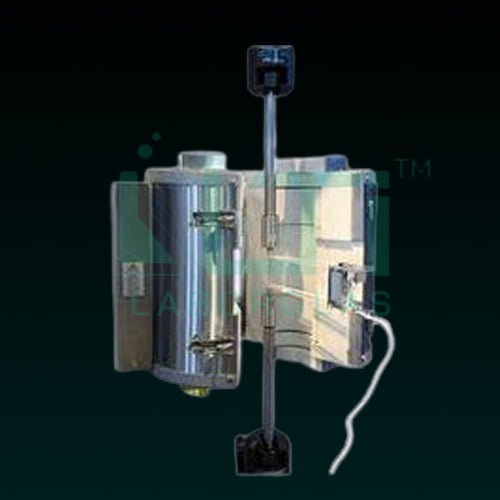

- This split hinge design permits easy observation convenient placement of process tube and easy of operation

- Specially ceramic insulation provides fast heat up and recovery and low temperature outer shell

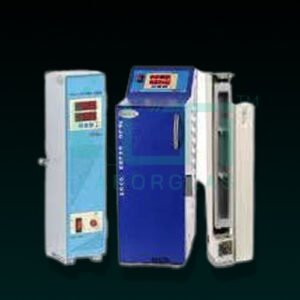

- Dual digital display compares actual and set point temperature

- Excess temperature protection by specially deigned solid state fuse

- Selection from horizontal or vertical mounting model

- Available pair of vertical mounting model

- Microprocessor based temperature controller to control temperature up to 1160c

A Split Type Tube Furnace is commonly used for:

- High-Temperature Processing: Conducting heat treatment and processes at elevated temperatures.

- Chemical Vapor Deposition (CVD): Depositing thin films on substrates through chemical reactions.

- Catalyst Activation: Activating catalysts for chemical reactions at high temperatures.

- Material Synthesis: Creating new materials through controlled high-temperature reactions.

- Laboratory Experiments: Utilized in scientific research for controlled high-temperature studies.

- Quality Control: Ensuring consistent conditions for testing and analysis.

- Annealing: Controlling the cooling of materials after high-temperature treatment.

- Metallurgical Processes: Applied in metallurgy for various heat treatment applications.

- Industrial Manufacturing: Employed in industries for specific high-temperature processes.

- Research and Development: Used in R&D activities for material and process development.