Features:

- Designed for multiple application including heat treating, ceramic firing, ashing and thermocouple calibration

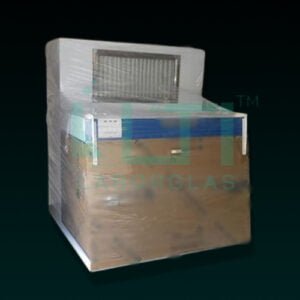

- Heavy duty steel construction for durability having epoxy powder coating finish in regular Model

- No exposed long lasting kanthal AI heating elements

- Maximum energy efficiency which is achieved being use of high thermal efficient ceramic insulation surrounding the chamber

- Solid state cutout removes power to heaters if unit exceeds maximum temperature

- Choice of solid state electronic temperature controller with digital indicator or microprocessor based temp. Controller having dual indication of “set” and “process” temperature with printer output

- Housing made of 316L matt finish in GMP model

- Maximum temperature:1200c, working temperature:1160c

- Operates on 239 volts

A Muffle Furnace (High Temperature) is commonly used for:

- High-Temperature Heat Treatment: Performing heat treatment processes at elevated temperatures.

- Ashing: Used for the combustion of organic materials to leave behind ash.

- Sintering: Applying controlled heating for the bonding of particles in ceramics.

- Material Testing: Studying the behavior of materials under extreme heat conditions.

- Laboratory Experiments: Utilized in scientific research for controlled high-temperature studies.

- Quality Control: Ensuring consistent conditions for testing and analysis.

- Metallurgical Processes: Applied in metallurgy for various heat treatment applications.

- Industrial Manufacturing: Employed in industries for specific high-temperature processes.

- Annealing: Used for the controlled cooling of materials after heating.

- Ceramic and Glass Processing: Firing and shaping ceramic and glass materials at high temperatures.