Features:

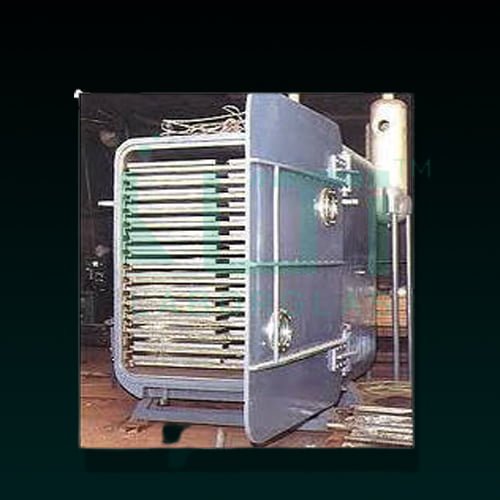

- Vacuum Dryers Large Chamber suitable for applications involving backing drying, curing aging, vacuum embedding plating and moisture determination utilizing a nitrogen atmosphere

- Stainless steel 304 inner chamber and exterior of mild steel finished in epoxy powder coated shade in regular Model

- Inner made of 316L and exterior 304 S.S matt finishes in GMP model

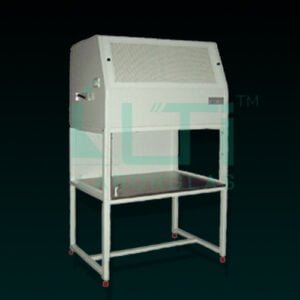

- Electronic digital single set point controller provided precise temperature control

- The door has tampered safety glass viewing window

- All 5 sides radiant warm wall heating elements for better temperature uniformity

- Positive locking door latch and heavy hinges ensures a tight seal to all vacuum levels

- Vacuum levels are controlled between 2 and nearly 30 inches HG large analogue and easy to read vacuum gauge

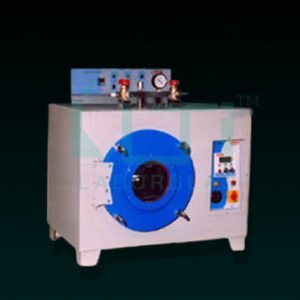

A Vacuum Dryer Chamber is commonly used for:

- Low-Pressure Drying: Drying materials under reduced pressure conditions.

- Heat-Sensitive Materials: Suitable for materials sensitive to high temperatures.

- Solvent Removal: Efficiently removing solvents from samples under vacuum.

- Pharmaceutical Drying: Used in pharmaceutical manufacturing for drying sensitive products.

- Laboratory Experiments: Utilized in scientific research for controlled drying.

- Chemical Processing: Supporting various chemical processes requiring vacuum drying.

- Product Dehydration: Removing moisture from products in a controlled environment.

- Quality Control: Ensuring consistent conditions for testing and analysis.

- Material Testing: Studying the drying characteristics of different materials.

- Research and Development: Applied in R&D activities for process development and optimization.