Product Details:

| Max Temperature | 300 DEGREE CELCUIS |

| Max Temperature (deg. Celsius) | 100-200, 200-300 |

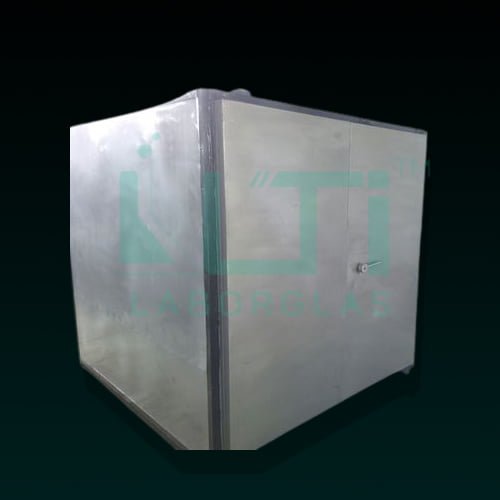

| Material | Mild Steel |

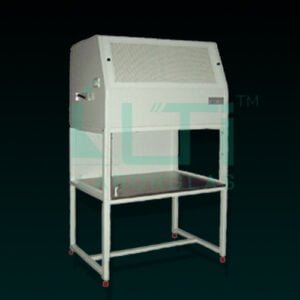

| Air-Flow Direction | Duel Air Flow, Vertical Down Airflow, Horizontal Air Flow |

| Type | Cabinet Ovens, Walk-In Ovens |

| Door Type | Double Door |

| Automation Grade | Automatic |

| Display Type | Digital |

| Warranty | ONE YEAR AGAINST MANUFACTURING DEFECT |

| Oven Type | INDUSTRIAL OVEN |

| Timer | YES |

| Inner Chamber | SS 304 |

| Capacity | 500-1000 Kg |

- Double walled in construction – highly insulated between two walls high quality glass wool.

- Interior of 304 stainless steel having buffed – finish.

- Exterior of M.S duly finished in grey powder coated shade

- Double Door, Fan for proper circulation of heat

- Microprocessor based PID temp. Controller. Temp. Range 50 Degreec to 300 DegreeC. Temp. Accuracy: +- 1C.

- A fully instilment door with sturdy brass/S.S. hinges. with spring ball type or magnetic latch.

An Industrial Oven is a versatile heating device used in various industrial applications. Here’s a brief overview of its uses:

- Heat Treatment: Used for heat treating materials to alter their physical or chemical properties.

- Curing Processes: Applied in curing processes for materials such as coatings, adhesives, and composites.

- Drying Applications: Utilized for drying manufactured products, parts, or materials in industrial settings.

- Baking and Cooking: Found in the food industry for baking and cooking large quantities of products.

- Preheating: Used for preheating materials or components before subsequent manufacturing processes.

- Aging Studies: Employed for accelerated aging studies to assess the long-term durability of materials.

- Annealing Processes: Applied in annealing processes for metals and other materials to relieve stress or improve properties.

- Powder Coating: Utilized in powder coating operations for curing and hardening coatings on metal surfaces.