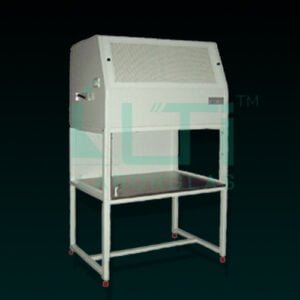

Product Details:

| Brand | LTI-LAB |

| Material | Stainless Steel |

| Chamber Volume | 100 Litre |

| Number Of Shelves | 2 |

| Warranty | 1 YEAR AGAINST MANUFACTURING DEFECT |

Stability Chamber (Humidity Oven) are designed for testing product shelf, life, stability and packaging electronic test.

Features:

- Specially designed to meet ICH guidelines for stability testing

- Double walled having inner 304 S.S chamber and exterior finished in epoxy powder coated shade

- Controls are simple solid state to set direct humidity % RH and temperature on DIGITAL indicator

- An independent window heater on glass window of main door helps visibility for test by eliminating condensation

- A perfectly designed cooling system to operate any temperature from 10 c to 70 c temperature accuracy: ±1 c

- Boilers are having solid state auto on level controller

- CFC free cooling system includes hermetically sealed compressor, fan motor & condenser

- Humidification through steam flow on circulation . humidity levels from 40% RH to 95% RH humidity stability :±3% RH

- Air circulation system ensures more stability of condition

- Shelves are S.S wire mesh 3 shelves with all units as standard

A Stability Chamber with Humidity Control, often referred to as a “Humidity Oven” or “Humidity Stability Chamber,” is specialized equipment with specific applications. Here’s a brief overview of its uses:

- Stability Testing: Used for stability testing of pharmaceuticals, chemicals, and other products under controlled temperature and humidity conditions.

- Product Shelf Life Studies: Conducts studies to assess the shelf life and stability of products in varying environmental conditions.

- Pharmaceutical Quality Control: Integral in pharmaceutical industries for quality control processes, ensuring product stability over time.

- Biological and Medical Research: Applied in laboratories for studies requiring precise control of temperature and humidity for biological or medical specimens.

- Climate Simulation: Simulates and controls environmental conditions, including temperature and humidity, to replicate real-world storage conditions.

- Material Testing: Used for testing the stability and durability of materials, coatings, and components exposed to controlled environmental conditions.

- Electronic Components Testing: Found in electronics manufacturing for testing the stability and reliability of electronic components.

- Industrial Quality Assurance: Employed in various industries for quality assurance processes that involve assessing product stability under different environmental scenarios.