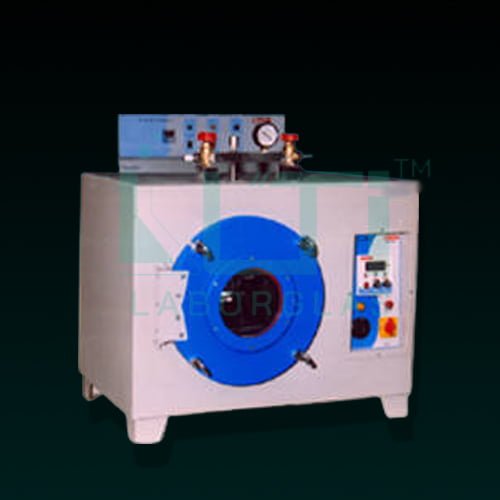

Product Details:

| Display | Digital |

| Air-Flow Direction | Vertical Down Airflow |

| Wall Type | DOUBLE |

| Ambent Temperature | 250 |

| No. Of Shelves | 2 |

Features:

- Most dependable and economical budgeted priced

- Chamber made of heavy gauge stainless steel year of corrosion resistant

- Exterior of M.S/GI sheet finish in epoxy powder coated shade

- Heat treated glass window leaves clear content view

- Silicone gasket and positive door latch assure tight seal at all vacuum levels

- Choice of temp. controller from solid state digital temp. controller or microprocessor based PID controller

- Two needle valves – one for vacuum and the other for flushing or inlet

- Maximum vacuum up to 30” hg

Technical Specifications:

| Part No. | Size | Temp. Controller | Temp. Range | Watts |

| 11070-A | 9”Dia x12” Depth | Digital | 50c to 200c | 700 |

| 11070-B | 12” Dia x 15”Depth | Digital | 50c to 200c | 950 |

| 11070-C | 15” Dia x18” Depth | Digital | 50c to 200c | 1100 |

| 11070-D | 9” Dia x 12” Depth | Microprocessor based PID controller | 50c to 200c | 700 |

| 11070-E | 12” Dia x 15” depth | Microprocessor based PID controller | 50c to 200c | 950 |

| 11070-F | 15” Dia x 18” Depth | Microprocessor based PID controller | 50c to 200c | 1100 |

A Round Vacuum Oven is a specialized equipment with applications in various industries. Here’s a brief overview of its uses:

- Vacuum Drying: Used for drying heat-sensitive materials under reduced pressure, preventing thermal degradation.

- Solvent Removal: Applied for efficient removal of solvents from materials through vacuum-assisted drying processes.

- Pharmaceutical Processing: Commonly used in pharmaceutical industries for drying and processing temperature-sensitive substances.

- Laboratory Research: Widely employed in laboratories for experiments and processes requiring controlled vacuum conditions.

- Precision Temperature Control: Equipped with precise temperature controls for accurate and reproducible drying conditions.

- Chemical and Biotech Applications: Used in chemical and biotechnological processes involving controlled drying and solvent removal.

- Material Processing: Applied for various materials processing applications, including curing, degassing, and resin infusion.

- Industrial Production: Found in industrial settings for production processes requiring vacuum-assisted drying or heat treatment.